Gungnir Industry is a high-tech company that integrates research, development, production, and sales of tungsten carbide burrs. The company is devoted to supplying highly precise, fast, and efficient cemented carbide products and services.

By introducing world-advanced 5-axis CNC grinding machines and 3-axis optical testing instruments, we can offer our customers good quality.

We consider our customers' demands as the guide to proceed and the resolution of users' application problems as the goal to achieve. The demands of customers at home and abroad will be met by perfect technologies and services.

Standard Cut Types

Cut MX - Double cut for general purpose use. Improves control and reduces chips

Cut MX - Double cut for general purpose use. Improves control and reduces chips

Cut M - Standard cut for general applications

Cut M - Standard cut for general applications

Cut W - Fast Mill cut for rapid stock removal of softer non-ferrous materials including plastics

Cut W - Fast Mill cut for rapid stock removal of softer non-ferrous materials including plastics

Special Cut Types

Cut C - Coarse cut for metal removal and finishing applications on non-ferrous metal alloys

Cut C - Coarse cut for metal removal and finishing applications on non-ferrous metal alloys

Cut F - Fine cut for improved finsh on all ferrous metals

Cut F - Fine cut for improved finsh on all ferrous metals

Cut ZX - Foundry cut for maximum stock removal, rough edges and foundry applications

Cut ZX - Foundry cut for maximum stock removal, rough edges and foundry applications

Cut L - Diamond cut for hardest materials and best finishes

Cut L - Diamond cut for hardest materials and best finishes

Cut MR - Chip breaker cut for fast stock removal. Improves control and surface finish

Cut MR - Chip breaker cut for fast stock removal. Improves control and surface finish

Cut SX - Aggressive cutting form for increased stock removal

Cut SX - Aggressive cutting form for increased stock removal

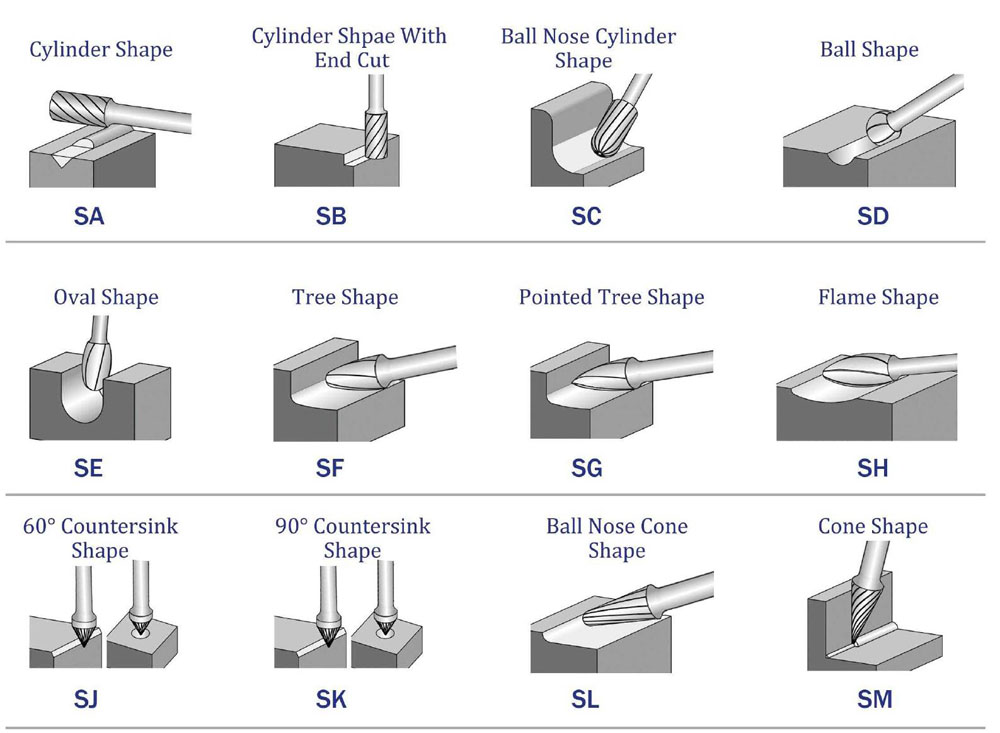

Application

Advantage:

• 100% Raw Material

• Premium grade tungsten carbide material results a long durability

•Anti-rust nickel steel shanks

•Innovative structure with sandwich low temperature welding brings a seamless solid bond between the heads and shank so that to avoid the burr head bullet fly.

•Full automatic production line ensures consistent superior quality and low labor cost

Packing requirement

•Individual package • Set Package

More information,please download our catalog.

If you have more customization requirements, please contact us